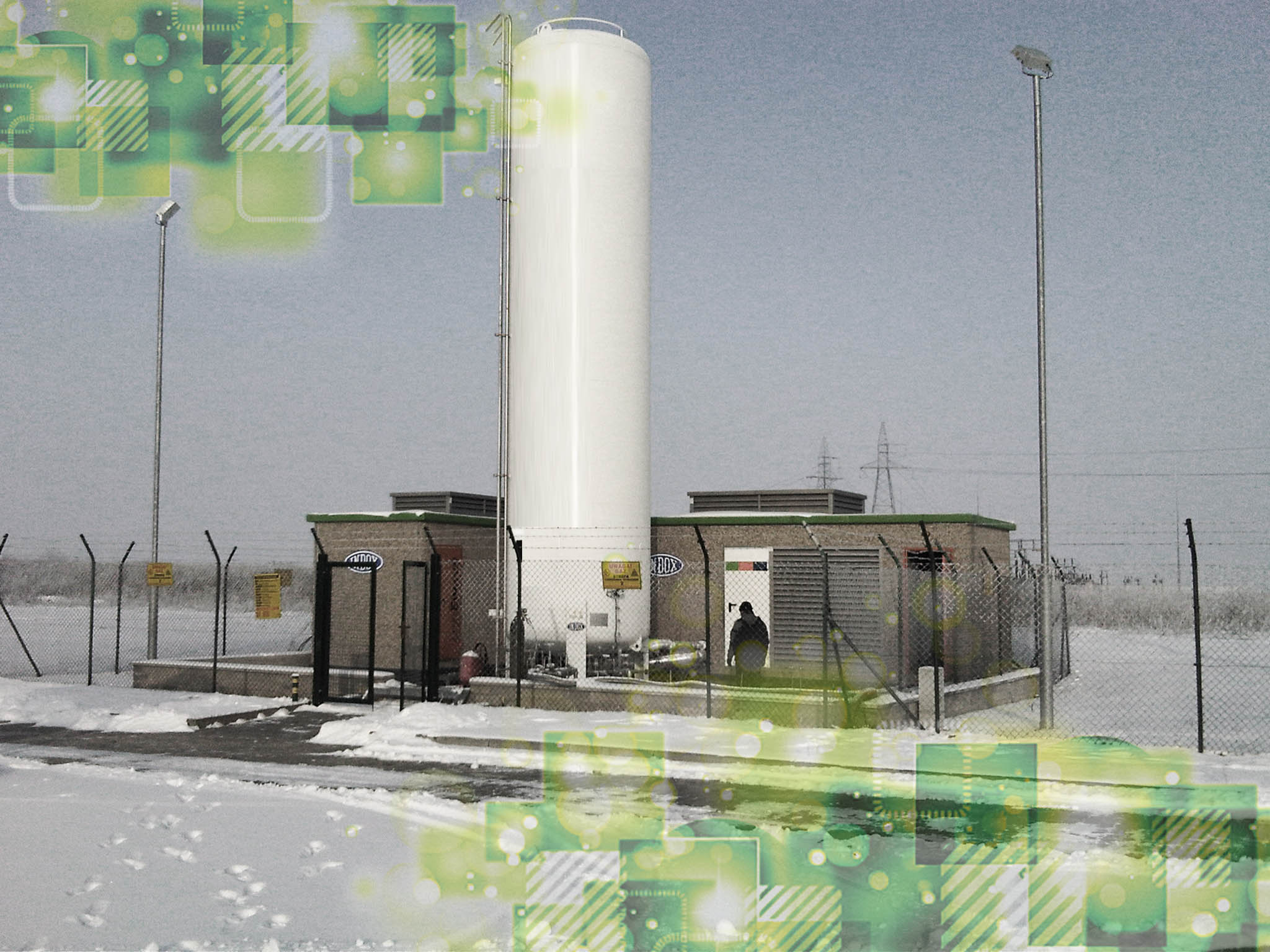

Natural gas fueling station

Today’s vehicles are filled with different kinds of liquefied gas: methane (natural gas), propane, butane and their mixtures (so-called hydrocarbon gases).

In addition, methane may be also used in its compressed state. The actual situation is clearly in favor that the unique real alternative as fuel in the methane.

The process:

In order to produce compressed natural gas (CNG), methane is pressurized in a methane compressor.

Its volume is decreased by 200–250 times.

Liquefied natural gas (LNG) is produced by chilling gas to minus 161.5 °C. The gas volume is decreased by 600 times.

LNG for trucks & ships:

1. USED IN TRUCKS DELIVERING GOODS

-

01

LNG has the potential to offer fuel cost savings when compared to conventional diesel.

-

02

It can also reduce sulphur emissions, particulates and nitrogen oxides, and help reduce greenhouse gas emissions from production to use.

-

03

In Europe and North America environmental regulations introduced in 2015 require shipping operators to reduce local emissions.

-

04

LNG fuel, which is virtually free of sulphur and particulates, can help them meet these requirements./p>

-

05

LNG has potential to be used by cruisers, ferries, barges and tug boats among others. It is already used as a fuel for vessels on inland waterways, such as ferries in Norway.

2. THERE ARE THREE DIFFERENT OPTIONS IN NATURAL GAS FUELING STATIONS

-

LNG

(Liquid Natural Gas) to supply LNG to trucks, buses, ships etz.

-

CNG

(Compressed Natural Gas) to deliver CNG to cars or vans.

-

LNG + CNG

Able to offer both previous otions.

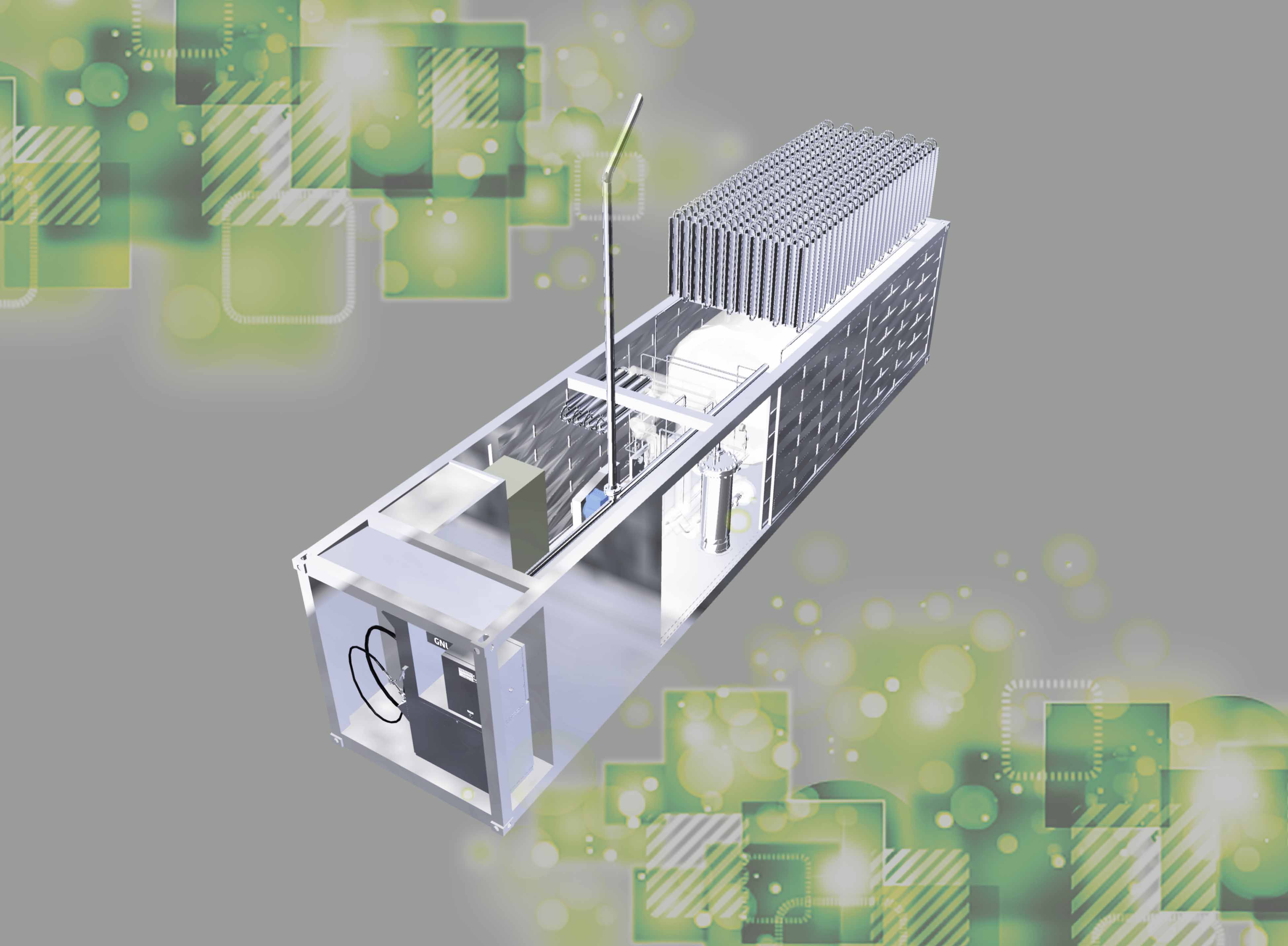

Main characteristics Plug & Play containerized simple fueling stations:

1. CNG NATURAL GAS FUELING STATION

-

01

Dimensions: ISO40 (2,5 X 12 X 2,4 m).

-

02

CNG Dispenser: Maximum of 80 Kg/minute. NGV2 connection.

-

03

Storage Capacity: 10m3 LNG deposit.

-

04

Actual Storage Capacity: 3.326 KG of LNG.

-

05

Daily Truck Load Capacity: 25 daily truck loads.

-

06

Daily Car Load Capacity: 120 daily car loads.

-

07

Control System: Automated loading system.

2. LNG NATURAL GAS FUELING STATION

-

01

Dimensions: ISO40 (2,5 X 12 X 2,4 m).

-

02

LNG Dispenser: 150 L/minute.

-

03

Storage Capacity: 10m3 LNG deposit.

-

05

Daily Truck Load Capacity: 25 daily truck loads.

-

05

Daily Truck Load Capacity: 25 daily truck loads.

-

06

Control System: Automated loading system.

3. LCNG NATURAL GAS FUELING STATION

-

01

Dimensions: ISO40 (2,5 X 12 X 2,4 m).

-

02

LNG Dispenser: 150 L/minute.

-

03

CNG Dispenser: Maximum of 80 Kg/minute. NGV2 connection.

-

04

Storage Capacity: 10m3 LNG deposit.

-

05

Actual Storage Capacity: 3.326 KG of LNG.

-

06

Daily Truck Load Capacity: 25 daily truck loads.

-

07

Daily Car Load Capacity: 120 daily car loads.

-

08

Control System: Automated loading system.

LNGnet 4.0:

ADD synergy offers the LNGnet 4.0 Integrated Connectivity Service. This service integrates the vehicles running on Natural Gas versus all the Natural Gas Service Stations linked to that network.

Both hardware and software, are located in the vehicles and the Service Stations in order to be accessed through the use of Smartphones or the different Terminals based in the central offices of the client’s company.

This allows the creation of apps that favour the interaction between the user and the service Platform that compiles all data from users and vehicles.

The coordination between these two sectors is key to gain efficiency:

1. REGARDING THE TRUCK:

-

01

Geo-location of the vehicle and the Service Stations.

-

02

Information about availability and LNG status.

-

03

Refuelling route optimization .

2. REGARDING THE SERVICE STATION:

-

01

Integrated Maintenance and Management by the Service Station.

-

02

Loading and Unloading as well as warnings and maintenance coordination.

-

03

Management of LNG supply in the Service Station based on LNGnet 4.0 information.

-

04

Possible connection between different Service Station operators.

The benefits are:

You can buy LNG on different suppliers

Normally LNG has more quality than gas pipe.

Access to locations without pipeline connection and/or electrical sources

Use of a less polluting fuel

End Users:

-

01

Liquid phase: Heavy duty fuel for trucks, buses, ships, mining industry…

-

02

Gas phase: Domestic or Industrial consumers.

Other Product & Services

Virtual pipeline

When there is no Natural Gas Pipeline, you can deliver LNG (Liquid Natural Gas) from the source to the final user by a Virtual Pipeline.

Learn More

Liquefaction plant

The liquefaction Plant is the key point in the virtual pipeline because it’s an easier and cheaper way of transporting Natural Gas over long distances.

Learn More

Truck loading facility

An LNG truck loading facility is the equipment to deliver to an LNG tanker the Liquid Natural Gas you have in a LNG Terminal Reception Plant.

Learn More

Logistics

The LNG is stored in tanks and transported by road tankers at a temperature of around -161°C and at a pressure between 1 and 3 bars.

Learn More

Bunkering

The shipping industry needs to reduce emissions from its use of fuels. Riverships, harbour tugs, tourist & passenger ships, ferries and Industrial ship transportation are moving fast to much cleaner fuels and LNG is the only full reasonable fuel they can use.

Learn More

Regasification plant

Once received and offloaded, the LNG is returned to cryogenic storage tanks, where it is kept at a temperature around -161°C prior to regasification.

Learn More